This blog post was originally published by Onit. It is reprinted here with the permission of Onit.

80 Forklifts for Indoor and Outdoor Logistics

Florim is a multinational company recognized in the production of ceramic surfaces.

With an innate passion for beauty and design, Florim has been producing ceramic surfaces for every building, architecture and interior design needs for over 60 years. Headed by Claudio Lucchese, the company has a past rooted in the Italian ceramic district and a present as an international trendsetter in the industry. It has more than 1,500 employees worldwide and a turnover of more than 584 million euros by 2022.

Florim Ceramiche is a company committed to technological innovation, with a particular vocation as an “early adopter”: in fact, it is often at the forefront of testing innovations on the market, such as indoor and outdoor localization technology, in order to benefit from their advantages and optimize logistics inside and outside the warehouse.

- 584 million in turnover

- 1500 employees

- 60 years of history

Customer Requirement: Indoor and Outdoor Localization Technology Aligned with Current Trends

Florim Ceramiche had already invested in innovative solutions to improve warehouse management: ten years ago, the company first approached the use of localization technologies and the implementation of a Forklift Guidance System software to meet the warehousing needs of the various factories.

As the reliability was no longer in line with the company’s objectives, along with unavailability from the supplier at the time, Florim Ceramiche turned to Onit with the need to implement an innovative technological solution capable of providing the X, Y and Z coordinates of the forklift with centimeter precision.

On-plant Solution: The Fiorano Project Starts from a PoC

As a result of the needs identified, Onit proposed to Florim Ceramiche the innovative Dragonfly solution: a technological system that, through computer vision and satellite kits, is able to maximize the accuracy of indoor and outdoor localization of moving assets (forklifts, LGVs, AMRs, robots, drones).

Realtime digital twin of the position of the forklift and the warehouse location

Realtime digital twin of the position of the forklift and the warehouse location

In the first design phase of the solution, in order to minimize the costs and to verify the technology, Florim and Onit agreed on a PoC (proof of concept), setting up 2 forklifts with the appropriate camera and various sensors: through the implementation and testing phase, the outdoor localization immediately demonstrated maximum accuracy, much more reliable than the previous technology.

A stratagem had to be used for the indoor localization part, as we will see later…

Dragonfly CV: Computer Vision’s Indoor Localization Solution

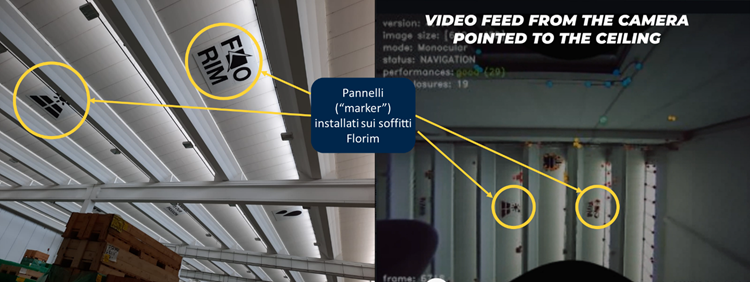

In the testing dedicated to the technology of indoor localization, carried out by means of computer vision – this is the name of the technology used by Onit with Dragonfly CV – thanks to a camera mounted on the roof of the forklift and to video recognition, the aim was to exploit the peculiarities of the ceiling of the Florim Ceramiche warehouse in order to locate the moving asset inside the warehouse.

Panels as view from the onboard camera and used by the Dragonfly algorithm to define the realtime coordinates (xy position) of the forklift

Panels as view from the onboard camera and used by the Dragonfly algorithm to define the realtime coordinates (xy position) of the forklift

During the operation, however, it became clear that the insufficient brightness in the warehouse was making it difficult to process high-quality images, and to solve this problem, Onit proposed a stratagem: placing markers in some parts of the ceiling, which would allow the Dragonfly CV technology to help in low-light conditions and ceilings with few distinctive features.

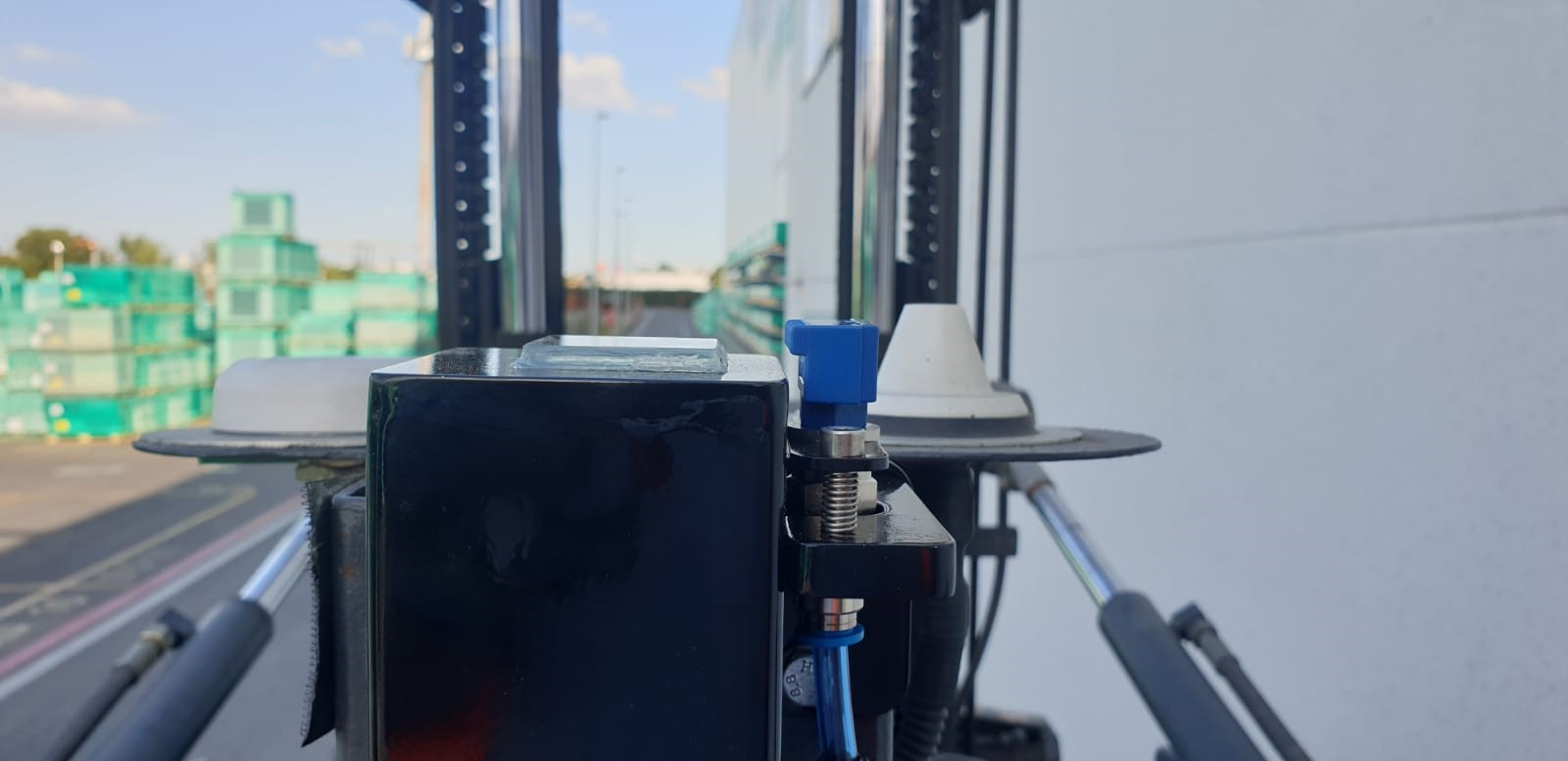

Onit completed the project by engineering a self-cleaning case to ensure optimal use of the Dragonfly CV software even in harsh environmental conditions (dusty, cold, rainy outside) that could contaminate the camera that captures the images useful for geolocation: through a time-controlled blow of air, the case removes dust and water droplets on the glass it protects.

Dragonfly Satellite: The Outdoor Localization Solution

The technological solution that makes outdoor tracking possible is called Dragonfly Satellite: this technology uses advanced satellite receivers, inertial sensing and RTK (real-time kinematic) corrections to best track the moving asset outdoors with centimeter accuracy.

Moving asset tracking data is processed in real time to provide the forklift driver with the correct information on the device on board the truck, making the transition between indoor and outdoor management technologies completely “seamless”.

Dragonfly camera with self cleaning system and GPS antenna/receiver

Dragonfly camera with self cleaning system and GPS antenna/receiver

Achievements; 80 Forklifts Set Up with Dragonfly Technology Between the Fiorano and Mordano Plants

The PoC at the Fiorano plant was successfully validated, leading to the expansion of the project to an additional plant (Mordano), with approximately eighty total forklift trucks equipped with Onit’s localization technologies.

As of today, Florim can now benefit from a new technology that allows for more accurate and timely tracking of forklifts both indoors and outdoors in real-time, surpassing the capabilities of its previous system.

Additionally, the Forklift Guidance System software enables Auto-ID functionality, allowing for self-identification of pallets during storage and retrieval without the need for a barcode reader. All of these benefits result in notable advantages, including:

- decreased errors in storing and retrieving items

- up to 20% improvement in forklift operator efficiency

- improved visibility in the control room into the activities of the forklift fleet in real time

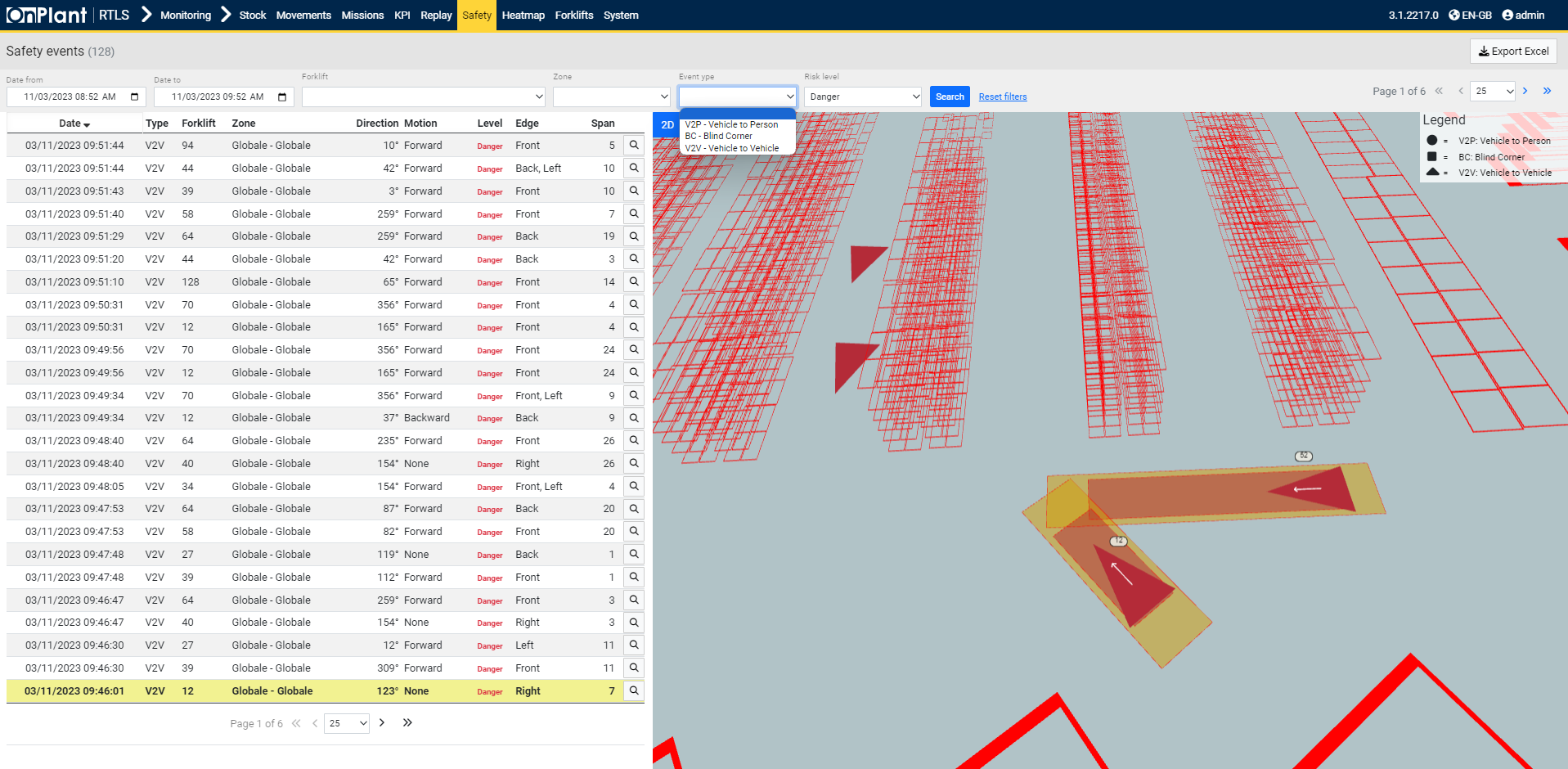

- increased safety for vehicle-to-vehicle and pedestrian in the warehouse and speed reduction control based on geofencing

An example of safety near-miss report, where the geographical area with hazardous events occurred is highlighted

An example of safety near-miss report, where the geographical area with hazardous events occurred is highlighted

Your Turn

If you have a warehouse and would like to implement this technology, it’s time to contact us. Several companies are adopting Dragonfly in their plan of innovation and it is proven to be a reliable and precise system for forklift tracking. Don’t miss this opportunity and connect now with our experts to discuss your project.

Contact Us Now: [email protected]