This blog post was originally published at Silo AI’s website. It is reprinted here with the permission of Silo AI.

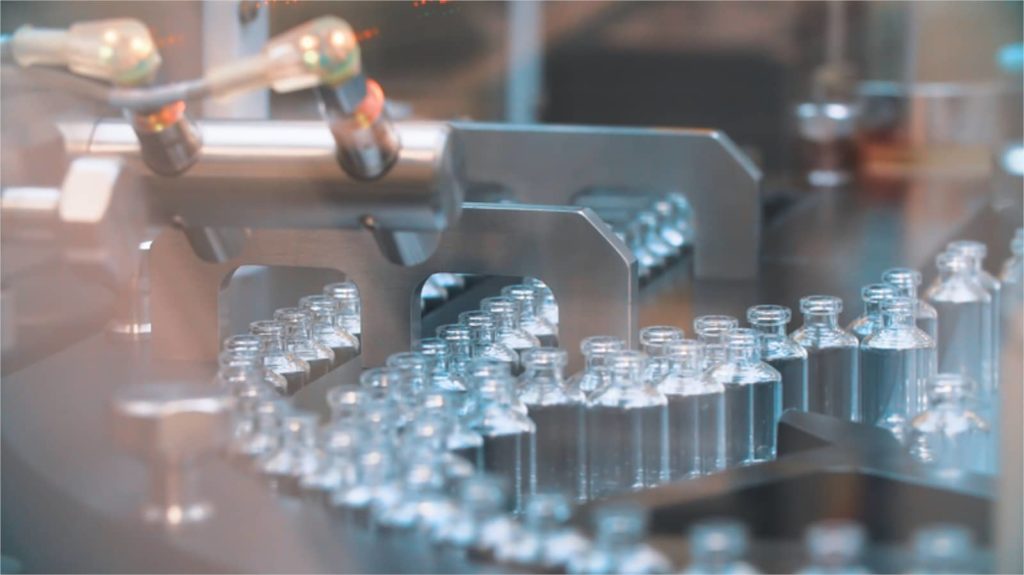

Together with Körber, Silo AI has developed a visual quality solution for inspection machines to control the quality of Covid19 vaccine ampoules.

The international technology group Körber and Silo AI, one of the largest private AI labs in Europe, have teamed up to accelerate the development of AI-driven visual quality control for the pharmaceutical industry. Together with Körber, Silo AI has developed a visual quality solution for inspection machines to control the quality of Covid19 vaccine ampoules. Körber Digital is currently the largest company builder for manufacturing efficiency in Germany.

In this video, our Chief Technology Officer, Niko Vuokko, explains Edge AI and introduces how Edge AI was utlizied for Körber’s requirements.

Changing traditional manufacturing and turning to cloud technologies, edge computing and AI for more efficient and sustainable manufacturing operations

Körber wants to change the traditional manufacturing industry into digitally run operations utilizing cloud technologies and edge computing AI. The aim is to turn manufacturing into more efficient and sustainable operations and create a win-win situation for everyone.

Regulations in pharmaceutics range from accuracy and speed to thermal limits – making the evaluation of the best possible edge hardware solutions crucial

Silo AI was asked to evaluate the best possible edge hardware solutions to control the quality of Covid19 vaccine ampoules. The evaluation needed to meet Körber’s requirements for pharma industry inspection machines and be a modular solution that modern software could adapt to many use cases.

Due to regulations in pharmaceutics – requirements like the accuracy and latency had to be taken into account. Additionally, edge hardware solutions have their requirements like processing power, memory size, and thermal limits.

In Körber’s case, the problem lay in latency and accuracy. In a factory setting, the decision-making is fast-paced. About 600 vials need to be processed per minute in addition to updating algorithms in real-time whilst simultaneously logging an accurate audit trail.

Results

- Silo AI evaluated the best possible edge hardware for pharma industry inspection machines to control the quality of Covid19 vaccine ampoules

- Together Körber and Silo AI built a solution that is certifiable and meets the most demanding production standards in pharmaceutics

- Built a visual quality solution running on the edge and optimized on precisely selected hardware, to ensure fast and accurate inference

“I firmly believe that manufacturing in the future will be driven by engineering processes using digital tools and technologies. This will result in safer machines and improved processing quality, which is vital, especially in pharmaceutics. It has been valuable to work with Silo AI, as there are often specific topics related to, for example, edge AI, for which we profit from working with a skilled partner. Working in partnership with Silo AI to access leading AI scientists with needed high-quality skills has been beneficial”

Daniel Szabo

CEO, Körber Digital