This blog post was originally published at Outsight’s website. It is reprinted here with the permission of Outsight.

3D LiDAR is a complex technology that enables unprecedented spatial intelligence. Many engineering choices are possible when building a new device.

This article is a continuation of the basic introduction to LiDAR technology that was provided in the earlier one. Before diving into the more technical details described below, be sure to read it!

Simply put, a LiDAR (Light Detection & Ranging) system times how long light takes to reflect off a target that is illuminated by its light source.

Because it generates its own light, it’s called an active sensor.

It operates in a variety of environments and contexts, such as at night and in direct sunlight, in contrast to existing 2D-based perception technologies like cameras (a passive sensor).

Compared to another active sensor like radar (radio detection and ranging), the laser light being used in LiDAR allows for much better resolution at distance – cm instead of meters.

The four components of any lidar

Each LiDAR device performs four main functions:

- Electron to photon conversion: A laser source generates its own light (it emits photons) when excited with electricity.

- Illuminating the field-of-view: A LiDAR must have a method for spreading the laser light across the zone of interest in order to produce a 3D image.

- Detecting the returning light: To convert photons back into electrons and calculate the distance of surrounding objects, a specific detector sensitive to the laser light being emitted is needed.

- All the previous operations are controlled by specific electronics, which includes the computation of the acquired data.

The following sections dive deeper into the first three components.

1. Laser sources

Since the laser’s discovery more than 60 years ago, extensive research has been done on it. Different kinds of lasers are used in various technological fields today.

These include liquid (dye) lasers, semiconductor lasers, gas lasers, solid-state lasers (also known as diode lasers) and fiber lasers.

LiDAR manufacturers use mainly different types of diode lasers (ie. Velodyne, Ouster, Innoviz, Hesai…) and fiber lasers (ie. Luminar, Aeye, Innovusion…)

Each of these two techniques emits laser light in specific wavelengths (or regions of the spectra) and has pros and cons:

- Diode lasers working between 800 to 1064nm : although they perform less well than Fiber lasers, they have the advantage of being simpler, smaller, and less expensive. These wavelengths are close to the visible range, so Eye Safety regulations have a greater influence on the amount of energy that they can emit.

- Fiber lasers working at 1550nm : they are (almost) not constrained by eye safety and can then deliver high power output, which improves signal-to-noise ratio, range, and measurement accuracy. However, fiber lasers are less suitable for integration into small LIDAR systems due to their complexity, and they are much more difficult to manufacture at scale and at an affordable price.

Types of lasers

There are mainly two types of laser diodes:

- An EEL (edge-emitting laser) emits light from the substrate’s edge. In a semiconductor wafer, a solid-state laser is grown with the optical cavity parallel to the wafer’s surface. This was originally used by Velodyne and Quanergy for their mechanical spinning LiDARs.

- In a VCSEL (vertical-cavity surface-emitting laser), the light is emitted perpendicular to the mounting surface, as opposed to an EEL, which emits light parallel to the surface. This allows fabricating many lasers on a sigle array and lowers the cost for the same number of points-per-second being delivered. This is used by Ouster among other manufacturers.

In the 1550nm region, fiber lasers’ LiDAR, such those used by Luminar, Aeye and Innovusion, also use a diode (in some cases several of them) to “pump” energy into a long fiber, that highly amplifies the signal.

In summary, fiber lasers operate much more effectively when price, size, and power consumption are less critical. Even with lower performance, diode-based LiDARs are more suitable for short-term mass production.

It’s hard to predict how the market will evolve, because fiber laser LiDAR manufacturers are greatly improving the manufacturing techniques and reducing costs, while diode-based LiDAR makers like Innoviz and Valeo are greatly enhancing their performance!

An important metric of any LiDAR, how many laser points per second it’s capable of measuring, is directly related to the laser source performance.

The repetition rate is a key performance indicator, measured in points per second. Traditional 2D LiDAR used in cartography used to emit at some 20 to 50k points per second. The most advanced LiDARs today emit several millions point per second.

The Peak power means how powerful each laser pulse is, which directly translates into detection range. The narrower the pulse duration or width the more efficient the LiDAR is for a given total energy budget, but also the better the accuracy.

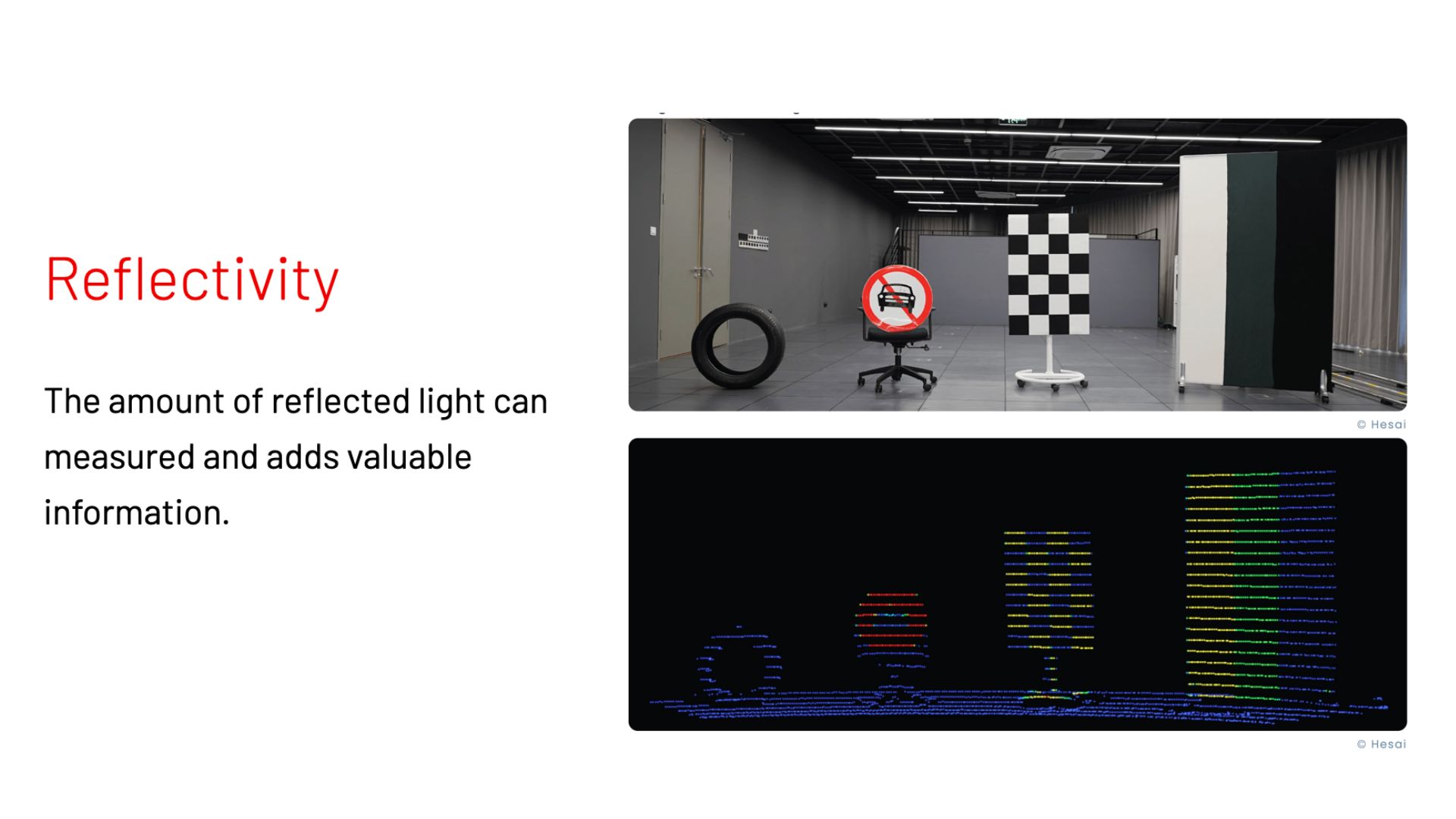

Reflectivity: the amount of energy returned to the detector depends on the type of material and angle of incidence among other factors, is an important piece of information that most LiDAR also provide.

2. Illuminating the field of view

A device that sends a laser pulse (or even a train of consecutive laser pulses) and measures the time it takes to get back is not a LiDAR. It’s called a range finder, and you can easily find them at affordable prices.

While you can wait 1 or 3 seconds for your range finder to provide distance measurements of a single spot in space, for 3D LiDAR to be useful it must provide:

- Range and reflectivity 3D images (called frames) at least 10 times per second.

- Illuminate a significant portion of the surrounding space (the field-of-view or FoV) with millions of points.

There are different techniques to illuminate the target field of view.

One method is to progressively illuminate each section of the field of view. In order to scan a different section at different times, the laser beam must be steered using a variety of mechanisms (spinning mirrors, spinning motors, micro-mirrors, etc.).

There are, by the way, other techniques to steer the laser light without moving parts, like Lumotive’s Light Control Metasurface, but these are beyond the scope of this article.

A different method is to diffuse the laser light so that a single pulse simultaneously illuminates the entire field of view (FoV). A matrix of sensors on the detector side will pick up a particular area of the space.

From the laser source perspective, that means that you require a much slower repetition rate but a much more powerful peak power per pulse. This method also requires the array of detectors to be easy to manufacture at scale.

Repetitive vs. non-repetitive scanning patterns

The vast majority of LiDAR manufacturers employ a repetitive scanning pattern, which means that each frame (3D image) generated by the device will be identical to the previous one (if the sensor is not moving and there are no moving objects in the Field-of-view). This is because each laser pulse will hit the same exact location frame after frame.

Companies like Livox / DJI employ a non-repetitive pattern where the firing angle of each laser beam varies over time. Therefore, even a static lidar in a static scene will eventually produce a much denser image.

Why is this useful? Understanding the “background” (the static portion of the scene) is crucial in many applications to quickly identify moving objects (by definition not part of the background).

Therefore, a non-repetitive LiDAR with a much lower repetition rate -and price!- (for example, 250k points per second as opposed to 2 million points per second) can be much more appropriately used in a variety of circumstances and contexts.

3. Detecting the returning light

The methods to detect the light greatly depends on the Laser source being employed: wavelengths below 1064nm can be detected using Silicon-based sensors, which means that they can be affordable and easy to manufacture.

Fiber lasers at 1550nm require other materials like InGaaS, that are harder to produce at scale.

Another aspect to take into account is the detection method.

The vast majority of LiDAR manufacturers, including Velodyne, Ouster, Luminar, Aeye, and Innoviz, employ what is known as the direct time of flight method (or ToF LiDAR). By directly timing how long it takes the laser light to return to the detector after hitting an object, the distance can be calculated.

However, a different approach, popularized by companies like Aeva, is quickly becoming mature: FMCW LiDAR (or frequency modulated continuous wave LiDAR), that uses coherent detection.

In simple terms, instead of sending pulses over time, FMCW lidar sends out a constant stream of laser light (continuous wave) and modifies its frequency at regular intervals (frequency modulated). This allows to both determine the location of objects and precisely measure their axial relative speed using the Doppler effect.

This technique has many advantages, including immunity to sunlight and other device interference. They typically operate in the 1550nm spectrum, with the advantages related to eye safety that we mentioned for fiber lasers.

The power consumption can be far lower (up to 1000 times), which translates into higher ranges and resolution for the same energy.

The FMCW’s instantaneous measurement of the axial relative speed of objects is a significant advantage. But it should be noted that these measurements only reflect the relative speed along the axis of the laser beam and not the velocity of the objects.

Conclusion

3D LiDAR is a complex technology that enables unprecedented spatial intelligence.

The laser source, the scanning method, the detector, and the target field-of-view are just a few of the engineering choices that can be made when developing a new device.

All of these factors can be combined, and some combinations perform significantly better in particular circumstances and contexts.

For example, a 360º FoV edge emitting laser-based Lidar with medium range and repetitive scanning pattern will be useless in indoor infrastructure applications with narrow aisles to be monitored, while very useful for robotaxis’ localisation and mapping in urban environments (…but not in highways!)

Moreover, the output of all these complex LiDAR devices is only a point-cloud (that is the RAW laser data points), whereas what is required in order to leverage the value of 3D data is ready-to-use actionable insight and information.

In addition, choosing which sensors to use, as well as effectively integrating them, let alone combining data from various manufacturers, is challenging due to the lack of any standard and the use of proprietary protocols by each manufacturer.

This is one of the reasons that made us build the first multi-vendor LiDAR simulator, you can learn more here.

Outsight’s mission is to create Lidar-based solutions that enable customers and partners to use the best combination of LiDAR models and manufacturers, while abstracting the complexity of the technology with an open and standard data format.

Learn more about our activity here, and some of our solutions in the examples here and here.

Kevin Vincent

Outsight