This blog post was originally published by Onit. It is reprinted here with the permission of Onit.

At Onit, we’re revolutionizing the efficiency and safety standards in warehouse environments through edge AI and computer vision. Leveraging our state-of-the-art Dragonfly and RTLS (real-time locating system) applications, we address the complex challenges inherent in chaotic and labor-intensive operations.

Our Dragonfly technologies are taking workplace safety to new heights with the latest release of Dragonfly 3! Featuring cutting-edge VSLAM (visual simultaneous localization and mapping) algorithms and a highly trained neural network, our solutions are evolving rapidly to meet the demands of industrial environments.

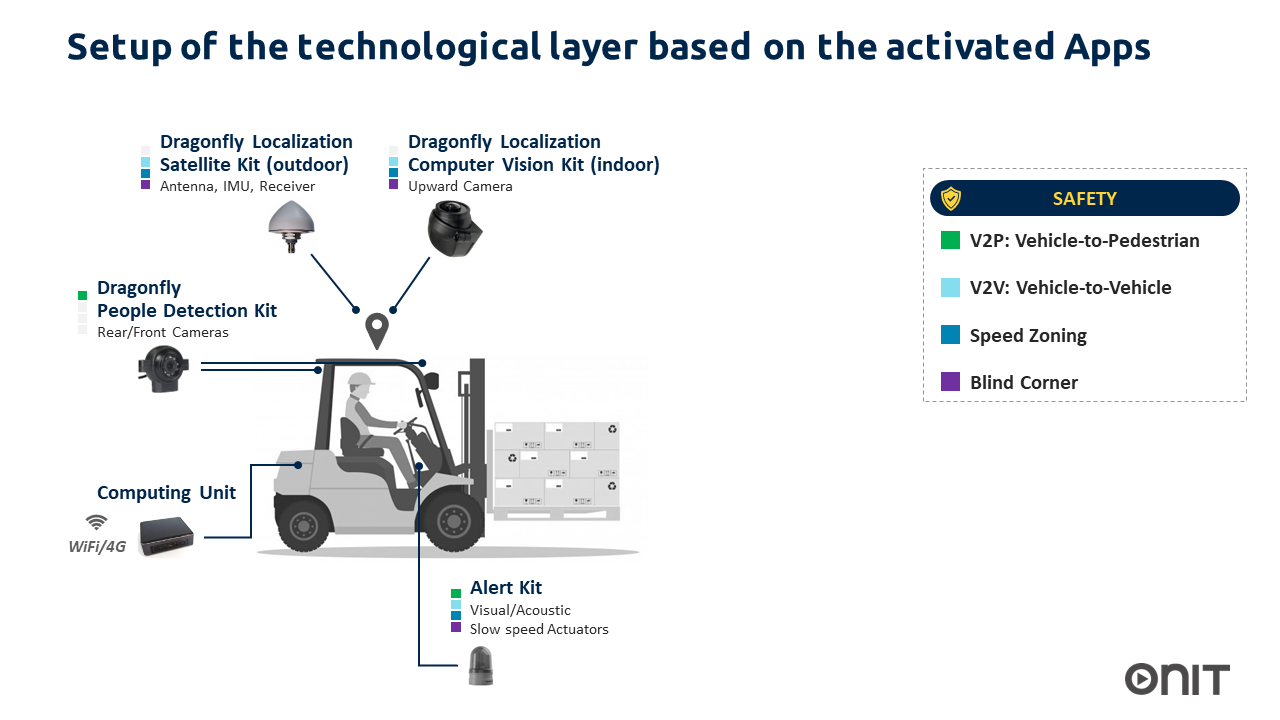

One of the most important RTLS application is safety: V2P (vehicle-to-pedestrian) and V2V (vehicle-to-vehicle) anti-collision, speed zoning and blind corner detection, that support your company in achieving a zero-incident vision in the workplace. Additionally, they elevate corporate image and branding through a strong commitment to workplace safety.

Building a Safer Workplace

There are five core principles of Onit’s solution to enhance safety for people and equipment:

- Best Approach for Accuracy and Reliability: Dragonfly localization and people detection, powered by computer vision, outperforms traditional radio proximity-based methods.

- Truck Vendor Independent: No lock-in with an industrial truck vendor’s safety solution; enables diverse forklift adoption while maintaining consistent safety standards.

- Actuating Systems: Configurable visual/acoustic alerts and automatic speed reduction (emergency brake) based on event risk-level for any industrial truck.

- Reporting: Data collection for objective insights, enhancing safety and maintaining overall operational efficiency.

- Certifications: Compliance with driver assistance systems (DAS) standards for industrial trucks, electromagnetic compatibility, etc.

Safety Solution Benefits

Approximately 374 million occupational accidents happen annually, of which about 2.78 million are fatal1

Injury and Fatality Reduction

Vehicle-to-pedestrian (V2P), speed zoning and blind corner enhance workplace safety, minimizing injuries and fatalities. This also results in substantial cost savings, ranging in double digits2.

Injury facts3: per-case average cost of wage and productivity losses, medical expenses, and administrative expenses:

- Death: $1,340,000

- Disabling injury: $41,000

Other indirect costs: OSHA fines, increase in workers compensation coverage (higher premiums), legal advisors, etc.

Operational Cost Reduction

- Vehicle-to-vehicle (V2V) and speed zoning minimize forklift accidents and safeguard infrastructure, leading to substantial cost savings.

- In the presence of safety solutions, insurance coverage and liability can be reshaped, reducing costs.

Corporate Image and Branding

- Strong commitment to workplace safety, elevates brand reputation and builds trust with stakeholders.

- B-Corp, ESG certifications attract investments, increase company value.

- A safe workspace increases employee satisfaction and enhances talent acquisition processes.

V2P – Vehicle-to-pedestrian Anti-collision

Avoid pedestrian accidents resulting from human errors by industrial truck drivers or pedestrians.

How does V2P vehicle-to-pedestrian work:

- Dragonfly people detection identifies the presence and relative distance of pedestrians around the industrial truck and determines the risk level.

- Alert kit for visual/acoustic alert and automatic speed reduction (emergency brake).

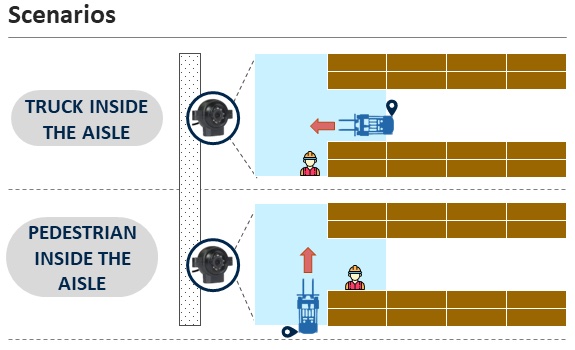

Scenarios of V2P

Scenarios of V2P

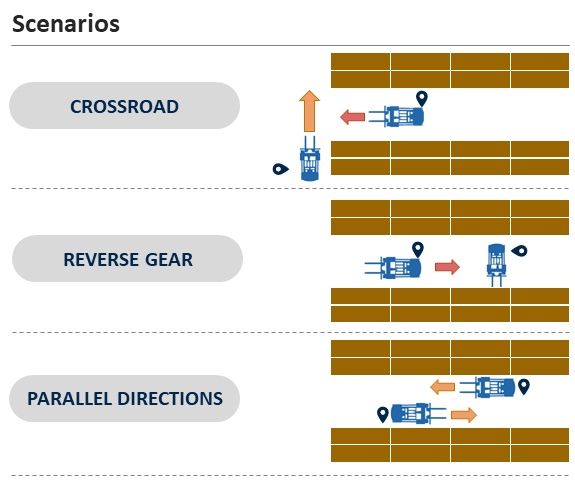

V2V – Vehicle-to-vehicle Anti-collision

Avoid accidents between industrial trucks.

How does V2V vehicle-to-vehicle work (dependent on real-time connection between trucks and server):

- Dragonfly localization sends the position, speed, and direction to the server.

- Safety V2V server-side application estimates collision risk between forklifts and communicates risk levels to each forklift.

- Alert kit for visual/acoustic alert and automatic speed reduction (emergency brake).

Scenarios of V2V

Scenarios of V2V

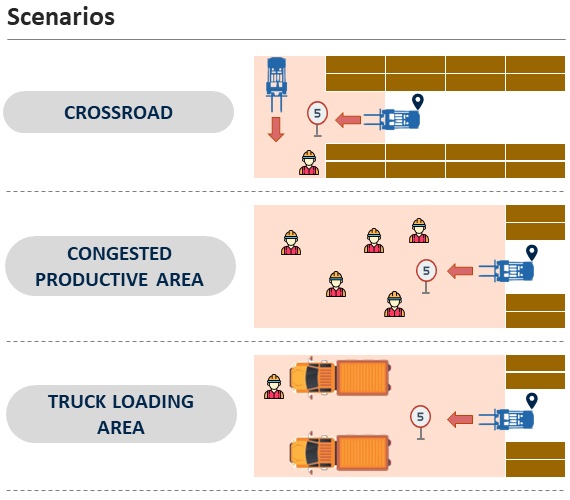

Speed Zoning – Adjusting Speed in Designated Zones

Avoid accidents in crowded or poor visibility areas involving people, industrial trucks, and infrastructure (racks, trucks, …).

How does speed zoning work:

- Definition of the speed zoning rules:

- Speed limits (typically one or two levels) (for example, the signage in the following picture)

- Geo-fenced areas (for example, the pink area in the following picture)

- Dragonfly localization determines whether the industrial truck is within a speed zoning area and, if so, checks if speed exceeds the limit.

- Alert kit for visual/acoustic alert and automatic speed reduction to comply with the speed limits.

Scenarios of Speed Zoning

Scenarios of Speed Zoning

Blind Corner – Low Visibility Intersections

Avoid pedestrian accidents caused by industrial trucks navigating low-visibility intersections.

How does blind corner work (dependent on real-time connection between trucks and server):

- Definition of the blind corner geo-fences (for example, the light blue area in the following picture).

- Dragonfly localization sends the position of the industrial truck to the server.

- Dragonfly people detection identifies the presence of pedestrians in the blind corner geo-fence through the wall-mounted camera and communicates it to the server.

- Safety blind corner server-side application communicates the presence of the pedestrians to the forklifts being in the blind corner geo-fences.

- Alert kit for visual/acoustic alert and automatic speed reduction (emergency brake).

Scenarios of Blind Corner

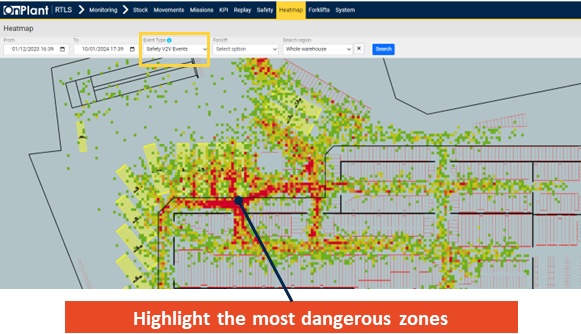

Safety Reports

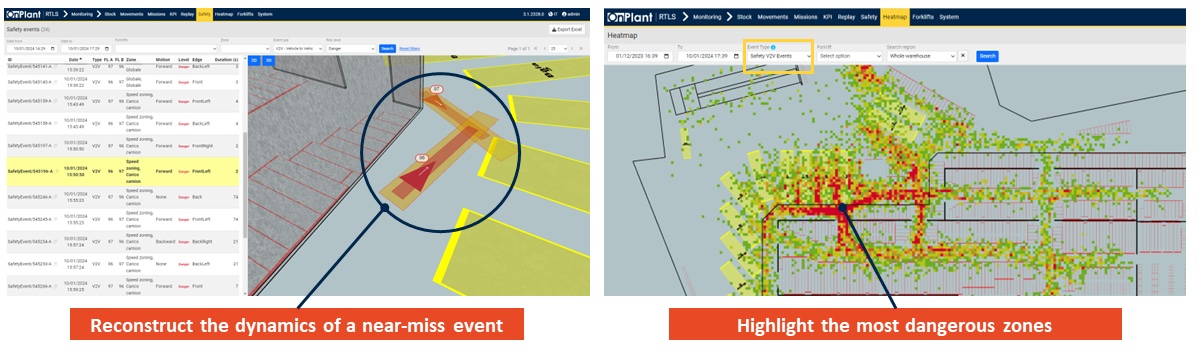

Safety reports enable you to reconstruct the dynamics of a near-miss event and to highlight the most dangerous zones, for example.

Thanks to the safety reports you can make strategic decisions, such as:

- Redesign warehouse pathways.

- Plan targeted training or reminders about safety rules based on identified gaps.

Examples of Safety Reports

Contact Us

References

- Source: United Nations Global Compact, A Safe and Healthy Working Environment

- Based on Amerisafe Group, on average, every dollar spent on improving workplace safety returns $4.41, https://amerisafegroup.com/the-real-cost-of-a-workplace-injury/

- Source: NSC National Safety Council, https://injuryfacts.nsc.org/all-injuries/costs/guide-to-calculating-costs/data-details/