For angle measurement and inline control of sheet metal bending processes, Vision Components supplies industrial-grade ready-to-use solutions, customer-specific systems, and OEM kits

October 13, 2021 – Vision Components will present its flexible modular system for optical angle measurement in sheet metal bending applications at its Blechexpo booth #5-222. The tested and proven laser sensors can be used with any controller. For easy use with DELEM controllers, they are already integrated in the DELEM software and only require activation. Many international press brake manufacturers use these measuring systems to check angular accuracy in metal processing.

Carsten Placke, Product Development & Managing Director at Placke GmbH, says: “We integrate VC nano3D-Z laser triangulation systems into our press brakes to enable real-time control of the immersion depth during the bending process. The systems are reliable, robust and do not require an external computer. They are already integrated in DELEM controllers and can thus be installed and used quickly and easily.”

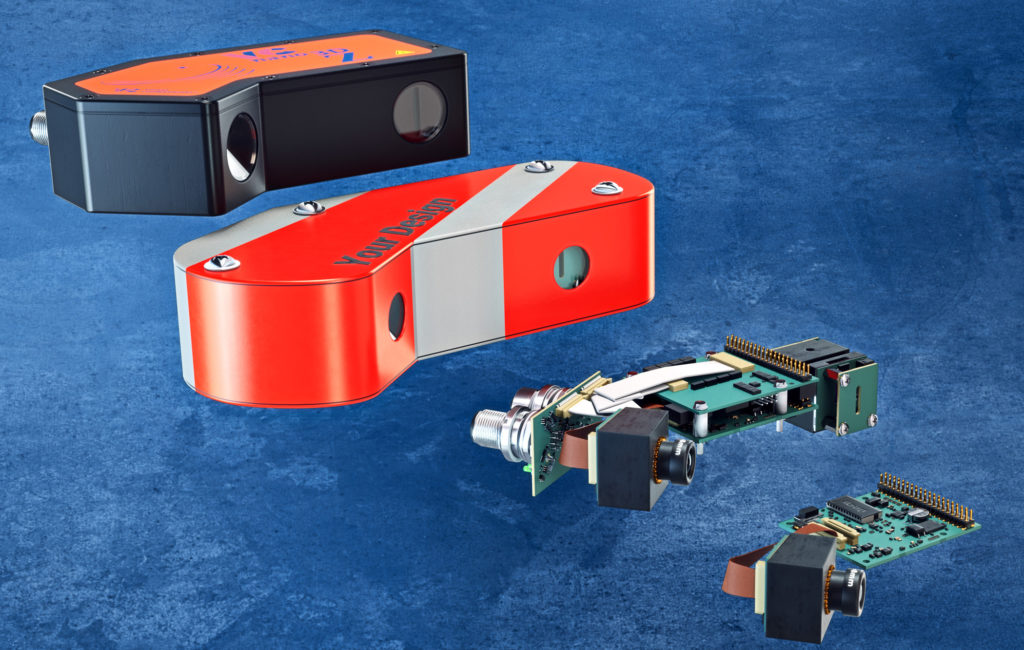

The compact VC nano3D-Z laser scanners calculate the angle onboard, without an external PC. They transmit the data to the machine control and thus allow for real-time contact pressure adjustment. Vision Components supplies the triangulation systems either as turnkey versions or with customer-specific housings and interfaces or as electronics kits for individual designs. In any case, machine builders and OEM manufacturers receive proven, industrial-grade components with assured long-term availability. Due to the optimal functional interaction of all components – camera module with optics, laser module, and electronics including programmed a FPGA module for 3D calculation – OEM customers significantly reduce their development time and costs as well as any design risks.

Vision Components was the manufacturer who launched the world’s first smart camera for industrial series applications in 1996. The company celebrates its 25th anniversary this year.

About Vision Components

Vision Components is a leading international manufacturer of embedded vision systems. The freely programmable cameras with powerful onboard CPUs perform image processing tasks on their own without the need for an additional computer. Vision Components offers OEMs versatile Linux-based embedded systems for 2D and 3D image processing, supplied as board cameras or in protective casings. These are complemented by a growing range of ultracompact MIPI camera boards, which connect to a variety of different CPU boards. In addition, Vision Components offers software libraries and develops customized solutions on request. The team of experts can draw on extensive knowledge and over 20 years of experience with imaging applications. The company based in Ettlingen in southwestern Germany was founded in 1996 by Michael Engel, the inventor of the first industrial-grade intelligent camera. More world premieres followed, including the world’s first intelligent vision sensors and the first-ever embedded 3D laser profiler. Today, Vision Components has sales offices in the United States and Japan and works with local partners in over 25 countries to provide consistent customer focus and readily available expertise throughout the world.