Visual Intelligence Gives Robotic Systems Spatial Sense

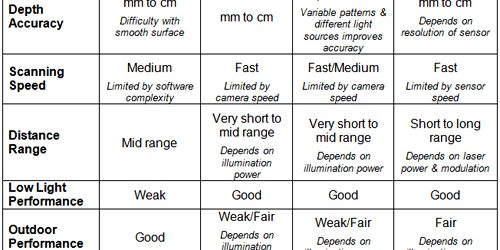

This article is an expanded version of one originally published at EE Times' Embedded.com Design Line. It is reprinted here with the permission of EE Times. In order for robots to meaningfully interact with objects around them as well as move about their environments, they must be able to see and discern their surroundings. Cost-effective […]

Visual Intelligence Gives Robotic Systems Spatial Sense Read More +